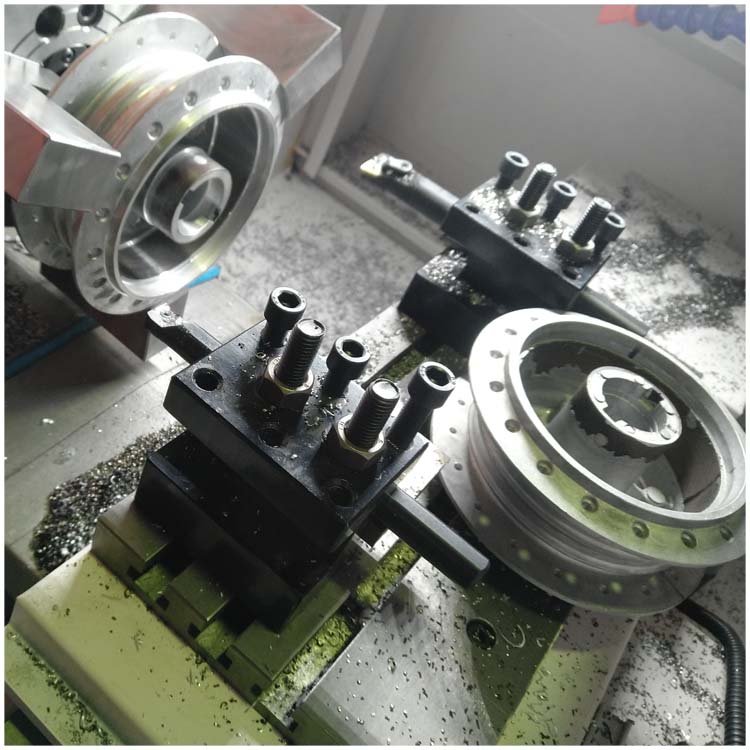

CNC lathe Machine is one of the most widely used CNC machine tools. It is mainly used for cutting the inner and outer cylindrical surfaces of shaft parts or  disk parts, the inner and outer conical surfaces of arbitrary cone angles, the complex rotary inner and outer curved surfaces, cylinders, and conical threads, etc., and can perform grooving, drilling, reaming, and reaming. Holes and borings etc.

disk parts, the inner and outer conical surfaces of arbitrary cone angles, the complex rotary inner and outer curved surfaces, cylinders, and conical threads, etc., and can perform grooving, drilling, reaming, and reaming. Holes and borings etc.

The CNC machine tool automatically processes the processed parts according to the pre-programmed processing program. We write the processing route, process parameters, tool trajectory, displacement, cutting parameters, and auxiliary functions of the parts into a processing program sheet according to the instruction code and program format specified by the CNC machine tool, and then record the contents of the program sheet On the control medium, and then input into the CNC device of the CNC machine tool, to direct the machine tool to process the parts

The characteristics of CNC lathe

CNC lathe is the abbreviation of digital control machine tool, which is an automatic machine tool equipped with a program control system. The control system can logically process and decode programs with control codes or other symbolic instructions, to make the lathe operate and process parts.

Cnc lathe machine and Manual lathe

CNC lathes have the following characteristics:

●High processing precision and stable processing quality;

●Multi-coordinate linkage is possible, and parts with complex shapes can be processed;

●When the processing parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

●The machine tool itself has high precision and high rigidity, can choose favorable processing dosage and has high productivity (generally 3~5 times that of ordinary machine tools);

●The machine tool has a high degree of automation, which can reduce labor intensity;

● Higher quality requirements for operators and higher technical requirements for maintenance personnel.

How to choose a CNC lathe?

Early preparation

To determine the process requirements of typical parts, the batch of processed workpieces, and to formulate the functions that CNC lathes should have is to make preliminary preparations and the precondition for a reasonable selection of CNC lathes: to meet the process requirements of typical parts.

The process requirements of typical parts are mainly the structural size, processing range, and accuracy requirements of the part. According to the accuracy requirements, that is, the dimensional accuracy, positioning accuracy, and surface roughness of the workpiece, the control accuracy of the CNC lathe is selected. Choose according to the reliability, reliability is the guarantee to improve product quality and production efficiency. The reliability of CNC machine tools means that when the machine tool performs its functions under specified conditions, it can run stably for a long time without failure. That is, the mean time between failures is long, and even if a failure occurs, it can be restored in a short time and put into use again. Choose a machine tool that has a reasonable structure, excellent manufacturing, and has been mass-produced. Generally, the more users, the higher the reliability of the CNC system.

Machine tool accessories and tools

Machine tool accessories, spare parts and their supply capabilities, and cutting tools are very important for CNC lathes and turning centers that have been put into production. When choosing a machine tool, it is necessary to carefully consider the matching of tools and accessories.

Classification of CNC lathe machine

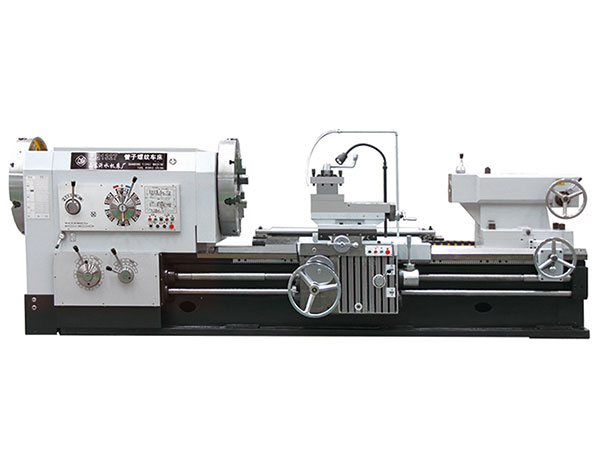

Horizontal cnc lathe has a small cnc lathe machine and heavy duty cnc lathe machine, For example, CK0640, CK6130, CK6132, CK6432, CK6136 CK6140 is a small lathes. CK6150 CK6180 CK61100 CK61125 is a heavy-duty lathe.

Slant bed cnc lathe TCK50 TCK42 lathe

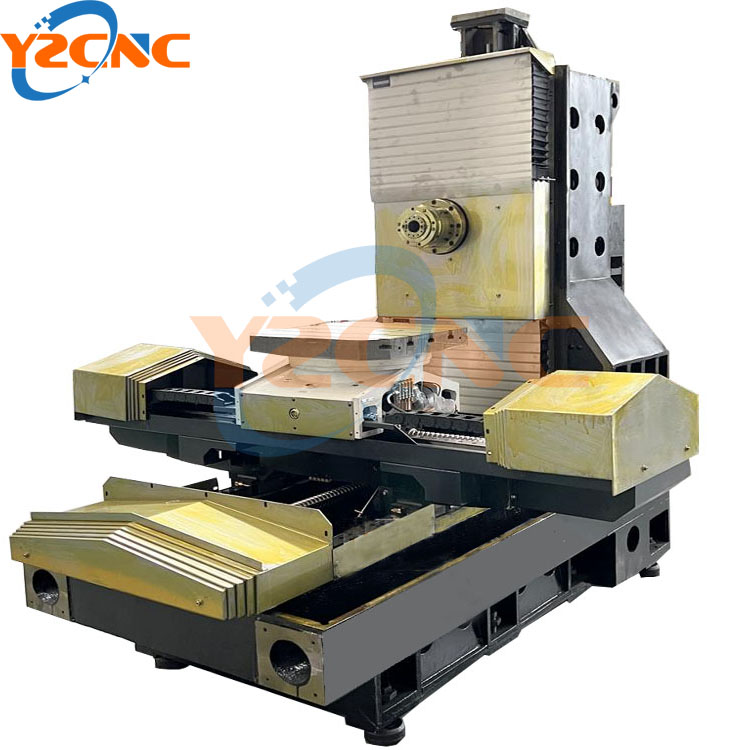

Vertical cnc lathe VCK850 VCK1000 vertical lathe

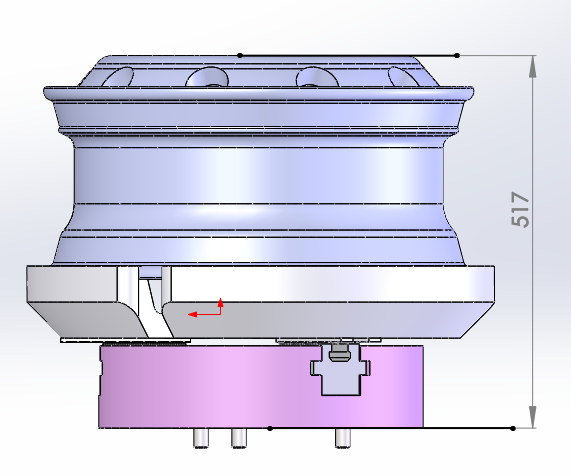

Cnc turning lathe machine and Manual lathe