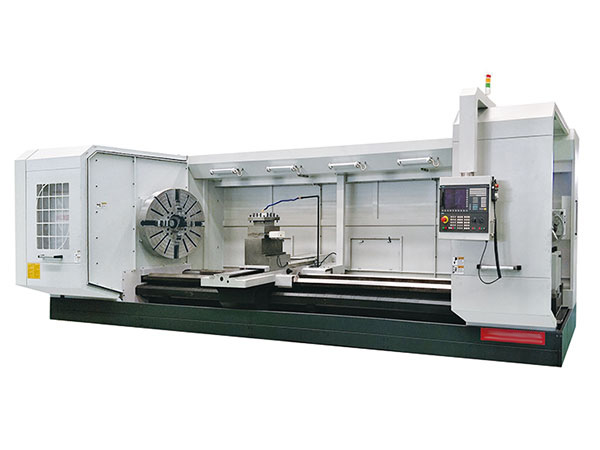

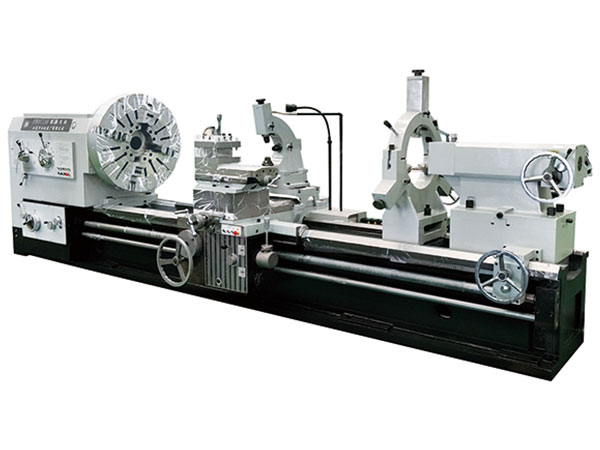

pipe threading lathe Main CNC pipe threading lathe and manual pipe threading lathe

The CNC systems that can be installed on Cnc pipe threading lathe machines mainly include GSK SIEMENS FANUC KND SYNTEC

Pipe Threading Lathe Features

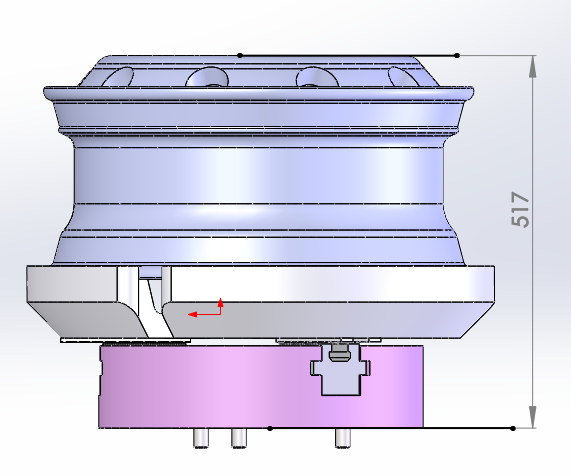

1. Big spindle bore and double chuck to ensure the process of big diameter pipe

2. One-piece bed adopts high-strength iron to ensure rigidity and precision

3. Ultrasonic frequency quenched guide-ways ensure good wear-resistance

4. Carriage and guideway contact surface use Turcite B to maintain accuracy.

What is the size of the spindle hole of the pipe thread lathe?

QK is cnc pipe threading lathe Q is manual thread lathe

Divided according to the size of the spindle hole QK1313/Q1313 Pipe threading lathe machine (spindle bore:130mm)

QK1319/Q1319 Horizontal threading lathe (Spindle bore :200mm) QK1322/Q1322 Thread lathe (spindle bore : 225mm)

QK1235/Q1325 Pipe thread lathe machine (Spindle bore:255mm) QK1327/Q1327 (Spindle bore:280mm)

QK1330/Q1330 (spindle bore :335mm) QK1335/Q1335(Spindle bore 355mm)

QK1332 QK1338 QK1343 QK1350 QK1363 Pipe threading lathe After continuous progress, I develop. Chinese pipe thread lathe manufacturers continue to improve product models and improve product quality. Now the spindle hole of pipe thread lathes can be produced from 130mm-700mm. The larger the spindle hole, the higher the requirements for machine tool manufacturing and the greater the difficulty

The main application industries and uses of pipe thread lathes

The QK and Q series Cnc pipe threading lathe is mainly designed for processing internal and external pipe threads including metric, inch, module, DP, and taper threads, as well as having all the common functions of a normal cnc lathe such as processing the inner bore and end face of shafts and disks. this series lathe machine is widely used in industries including petroleum exploitation, minerals mining, chemical piping, and geological prospecting, it is high-efficiency equipment in processing and repairing drilling pipes, drilling rods, thread coupling, and so on.

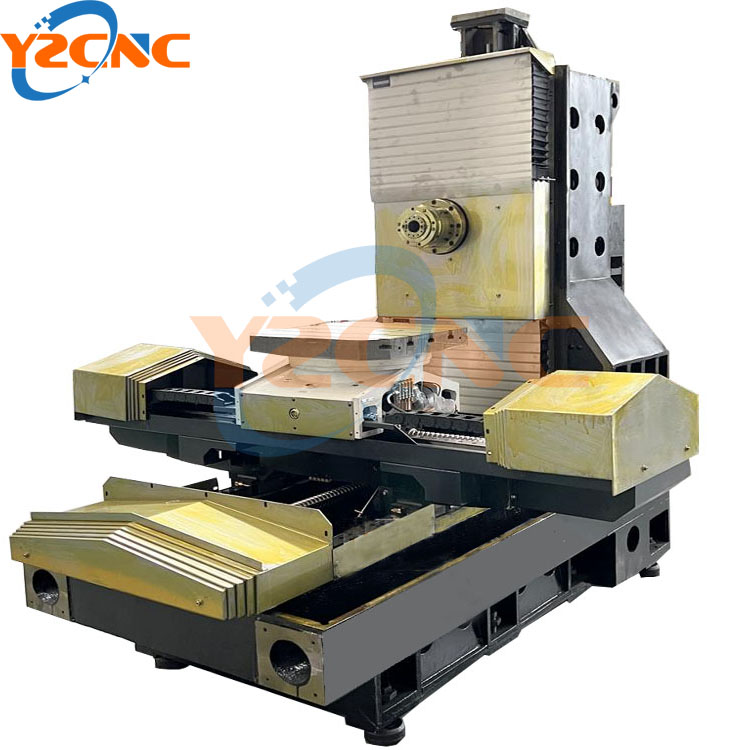

Bed of pipe thread lathe

Have Horizontal pipe thread lathe machine and slant bed cnc pipe threading lathe

The width guide rail of the pipe thread lathe

The larger the width of the guide rail, the stronger the stability and load-bearing capacity of the machine tool

pipe thread lathe has 400mm 55omm 600mm 650mm 700mm 750mm

The best manufacturer of pipe thread lathes in China YZCNC Machinery

How to maintain the operation rules of pipe thread lathe

The operator must be familiar with the general performance, structure, and rotation system of the lathe, and it is strictly forbidden to use the equipment with super performance

Pipe Thread Lathe machine Before work:

1. Check whether the operating handle, switch, and knob is in the correct position, whether the operation is flexible, and whether the limit and safety devices are complete and reliable.

2 Turn on the power and run the empty car at low speed, and if there is any abnormality, stop the machine for inspection or report it to the maintenance personnel.

3 Check whether the height indicated by the liquid level in the oil standard is appropriate, whether the oil passage is unblocked, and add enough lubricating oil to the specified parts.

4 Run the machine empty at low speed for 3-5 minutes, and start working after confirming that the lubrication, electrical system, and various parts are operating normally.

Pipe Thread Lathe machine Working:

1 The use of super performance is strictly prohibited.

2 It is forbidden to place objects on the guide rail surface and beam surface of the machine tool.

3 It is strictly forbidden to beat, straighten and trim workpieces on the worktable.

4 Clamping workpieces and tools must be firm and reliable.

7 Correctly use the tool holder rotation device and clamping mechanism.

8 Reasonably select the speed and cutting amount.

9 When the machine tool is running, the operator is strictly prohibited from leaving the job post.

10 If any abnormal phenomenon occurs during operation, stop the machine immediately, find out the cause, and deal with it in time.

Pipe Thread Lathe machine After working:

1 All joysticks, switches, and knobs must be placed in the stop position, and the power supply must be cut off.

2 Carry out routine maintenance.3 Fill in the shift records of fixed equipment operation records.

Pipe Thread Lathe machine maintenance procedures

1 Carry out lubrication adjustment work according to the patrol inspection position and lubrication chart to ensure the number of lubrication in the shift.

2 Check the oil mark page and the oil supply status of the oil pump.

3 Do a good job of cleaning the oil holes and lubricating parts of each part and cover them with dust shields.

4 During the operation, according to the replacement of different processing materials, do a good job in cleaning chips and oiling and lubricating.

4 Before leaving get off work, clean the bed surface, spindle box, toolbox, and all parts of the dust, and iron filings, and apply anti-rust oil.