Menu

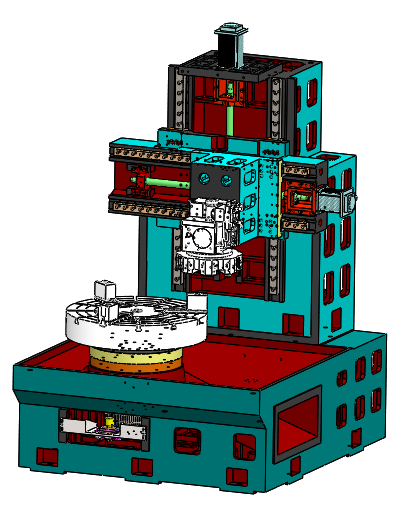

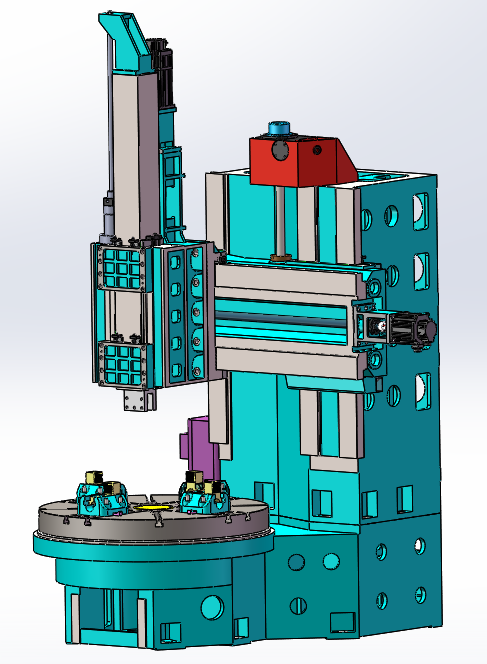

VTK1270 CNC Vertical Lathe single-column type is an automatic CNC machining machine tool for machining inner and outer cylindrical surfaces,  conical surfaces, end faces, grooving and chamfering of parts. It is especially suitable for vehicle brake hubs, wheel drums, clutch pressure plates, flywheel housings, etc. Processing of parts.VCK1270 Vertical lathe Single-column vertical guide rail structure, the column, base and sliding seat are all made of high-grade gray cast iron resin sand casting process, and have been subjected to aging treatment; the guide rail adopts roller-type heavy-duty linear guide rail, which has large load capacity and high precision; reasonable structural design , perfect processing and assembly technology to ensure the long-term stability and accuracy of the machine tool.

conical surfaces, end faces, grooving and chamfering of parts. It is especially suitable for vehicle brake hubs, wheel drums, clutch pressure plates, flywheel housings, etc. Processing of parts.VCK1270 Vertical lathe Single-column vertical guide rail structure, the column, base and sliding seat are all made of high-grade gray cast iron resin sand casting process, and have been subjected to aging treatment; the guide rail adopts roller-type heavy-duty linear guide rail, which has large load capacity and high precision; reasonable structural design , perfect processing and assembly technology to ensure the long-term stability and accuracy of the machine tool.

1. CNC system: GSK980Tdi

Feed motor 3.5KW/22NM 3.5KW/22NM (brake)

Spindle motor 55kW (rated speed 700, rated torque 700NM)

2. A2-11 spindle unit;

3. Taiwan Shangyin precision lead screw; Taiwan Shangyin roller linear guide.

4. Automatic centralized forced oil lubrication for screw and guide rail

5. Nitrogen balance system.

6. Mobile hand pulse generator, alarm light.

7. Cooling part.

8. Full protective sheet metal shield; pneumatic sliding door.

9. 8-station hydraulic turret; matching hydraulic station.

10. 1000mm three-jaw chuck

11. Chain chip conveyor and chip flushing device.

FANUC /SIEMENS/KND/SYNTEC

Vertical lathe Chuck Have Manual Chuck or hydrualic

Turret Can option Driven Turret Tool

| ITEM | |

| Workpiece Maximum turning diameter | 1250MM |

| Workpiece Maximum machining diameter | 1000MM |

| Vertical travel distance of turret tool(Z AXIS) | 800MM |

| Horizontal travel distance of Turret tool( X-axis) | -50-650mm radius distance |

| Distance from a lower plane of tool rest to upper plane of chuck | 0-800mm |

| Spindle Model | A2-11 |

| Spindle Load-bearing | 2000kgs |

| Spindle speed | 50-500rpm |

| Spindle output torque | 1960NM |

| Spindle motor power | 55kW 750RPM 700NM |

| X-axis rapid feed speed | 15m/min |

| Z-axis rapid feed speed | 15m/min cutting cutting |

| Cutting feed rate | 0.1-5000mm/min |

| X-axis motor power, torque | 3.5 kW /22NM |

| Z-axis motor power, torque | 3.5 kW /22NM Brake |

| Turret tool | 4/8 |

| Cutter bar section | 32×32mm boring bar 50/60mm |

| Chuck | 1000mm Manual chuck |

| Positioning accuracy | ±0.0075mm |

| Repetitive positioning accuracy | ±0.004mm |

| Machine weight | 12500kg |

| Machine size | 2600×3050×3200mm |

The main shaft of the machine tool is driven by a wide-area high-torque servo motor, which can be used for low-speed high-torque, powerful heavy cutting, or high-speed cutting. Meet both roughing and finishing needs

The main shaft of cnc vertical lathe adopts high-precision double-row cylindrical roller bearings, double-row thrust angular contact ball bearings, and double-row cylindrical roller bearings; auxiliary cylindrical roller thrust bearings. This configuration structure has the largest bearing capacity, can withstand larger cutting force and feed force, has higher radial stiffness and axial stiffness, and has higher rotation accuracy.

The X and Z-axis servo motors directly drive the precision ball screw pair through the flexible coupling, which can minimize the backlash and have high positioning accuracy. The Z-axis lift is equipped with a nitrogen balance system to improve the quality of the machine tool to achieve high-speed, high-precision machining and reduce the load of the servo motor to increase the life of the machine tool.

The X and Z-axis servo motors directly drive the precision ball screw pair through the flexible coupling, which can minimize the backlash and have high positioning accuracy. The Z-axis lift is equipped with a nitrogen balance system to improve the quality of the machine tool to achieve high-speed, high-precision machining and reduce the load of the servo motor to increase the life of the machine tool.

The X and Z axes adopt precision ball screw pairs and special bearings for ball screws to meet the requirements of high rigidity and high precision cutting. The screw support adopts a pre-stretched structure, which greatly reduces the influence of thermal deformation on the accuracy of the machine tool during long-term operation.

The X and Z axes adopt an advanced centralized automatic lubricating device, which is automatically and intermittently lubricated at regular intervals, and the work is stable and reliable.

The tool holder of the cnc vertical lathe can choose to adopt various forms such as a multi-station turret or row tool, with accurate precision and high efficiency.

This machine tool can be equipped with CNC systems of well-known brands at home and abroad such as Guangzhou CNC, Beijing Kaiendi, FANUC, etc. according to user needs.

Choose the right size vertical lathe according to the diameter and weight of the workpiece

The processing depth of the inner hole is also a very important reference standard It is best to provide drawings and let the vertical lathe manufacturer help you choose.

YZCNC Vertical lathe manufacturer Can provide you with professional solutions.