Vertical cnc Machining center Machining vibration, also known as chatter, is a common problem in manufacturing, leading to reduced machining quality, shorter tool life and increased machine wear. Several factors can cause vibration in vertical center machining, including the machine tool, cutting parameters, tool design, workpiece material and cooling system. In this article, we’ll explore some common causes of machining vibration and some strategies to mitigate it.

Vertical cnc Machining center Machining vibration, also known as chatter, is a common problem in manufacturing, leading to reduced machining quality, shorter tool life and increased machine wear. Several factors can cause vibration in vertical center machining, including the machine tool, cutting parameters, tool design, workpiece material and cooling system. In this article, we’ll explore some common causes of machining vibration and some strategies to mitigate it.

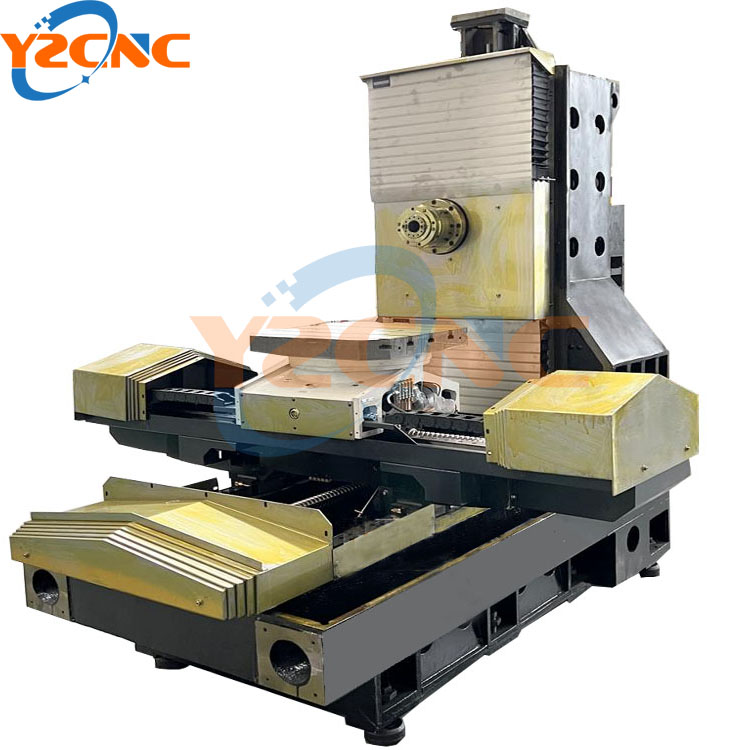

Machining Center Rigidity

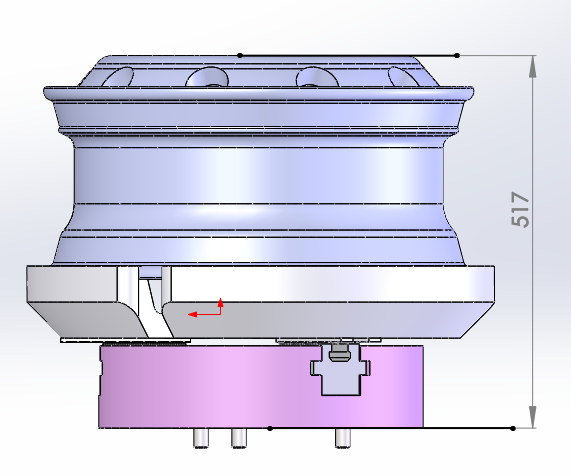

One of the most important factors in machining vibration is the stiffness of the machine tool. If the machine tool is not rigid enough, it will bend under cutting forces, causing vibrations. When we purchase a machining center, we must choose a machine tool that suits our workpiece. Machining center manufacturers and lathe manufacturers must strictly control the materials used and selected materials for machine tool castings when selecting machine tool castings. Machine tool designers must have sufficient experience in designing a reasonable vertical machining center structure. When purchasing a machine tool, in addition to considering the price of the machining center, the quality of the machining center should also be considered.

Machining Center Cutting Parameters

Machining Center Cutting Parameters

The cutting parameters used during machining can also cause vibrations. In particular depth of cut, feed rate and spindle speed all affect the stability of the cutting process. If any of these parameters are too high, the tool may become overloaded and start vibrating. To prevent this, the machining center operator should carefully select cutting parameters appropriate for the workpiece material and the cutting tool being used.

Machining Center Workpiece Tool Design

Tool design also affects machining vibration. If a tool is not properly designed, it may deflect excessively or vibrate during machining. To prevent this, manufacturers should select cutting tools designed for the type of machining performed and the workpiece material used.

Work material

The material processed by the vertical CNC machining center will also affect the processing vibration. For example, a particularly hard or brittle material may vibrate more easily than a softer, more malleable material. To reduce vibration, machine tool operation may require selecting cutting tools designed for the workpiece material or adjusting cutting parameters to account for material properties.

Machining Center Cooling System

The coolant system used during machining also acts as a shock absorber. If coolant is not properly delivered to the cutting zone, it can cause heat buildup and increase the likelihood of vibration. To prevent this, machining center manufacturers should ensure that coolant is delivered to the cutting area at the correct rate and pressure.

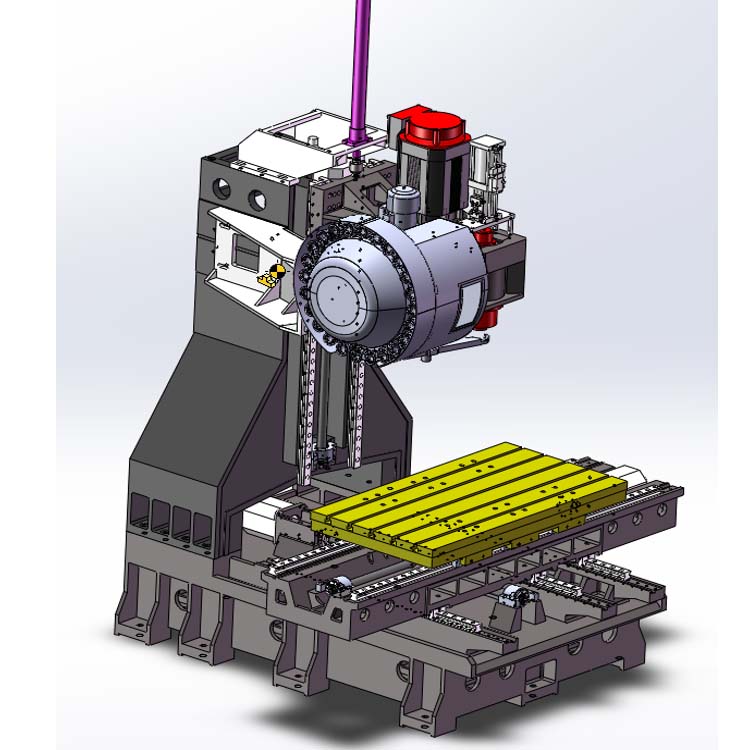

Mitigation Strategy of Machining Vibration in Machining Center?

Adjust cutting parameters

One of the most effective ways to reduce machining vibration is to adjust the cutting parameters used during machining. This may include reducing the depth of cut, slowing the feed rate or reducing the spindle speed. By adjusting these parameters, machining center manufacturers can reduce cutting forces and increase the stability of the machining process.

Machining centers use vibration damping systems

Another way to reduce machining vibration is to install a vibration damping system on the vertical machining center. These systems can include various types of damping materials, such as viscoelastic materials or tuned mass dampers, which absorb some of the vibrational energy and prevent it from affecting the machining process.

Upgrade Machine Tool Rigidity

If machining vibration is a chronic problem, the machining center manufacturer may need to invest in a higher quality machine tool with a stronger design. This may involve upgrading to a machine tool with a heavier frame or more advanced damping system, or it may involve retrofitting an existing machine tool with additional damping or strengthening components.