Menu

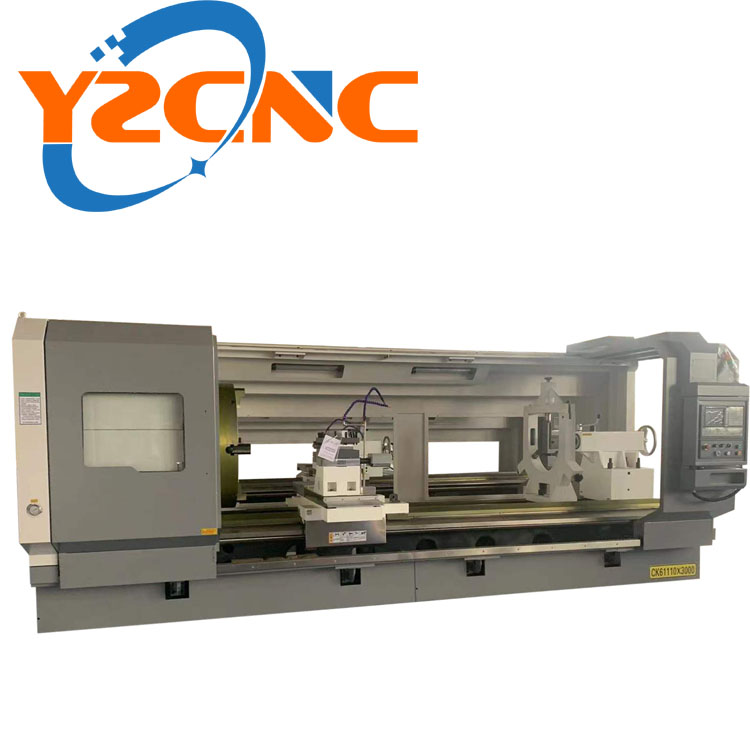

CK61100 Cnc Lathe Machine is heavy machining lathe machine Rail width of 755 mm Max. swing over bed 1100mm. Horizontal cnc lathe machine  structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

1. Lots of experience went into the design and construction of this machine bed featuring large guides that are hardened, ground, and counter-laminated.

2. Headstocks of the main spindle and gears were constructed to ensure optimum temperature balance and minimum heat influence.

3. Heavy-duty tailstock is easy to handle and features high clamping force.

4. Heavy-duty horizontal CNC lathes adopt wide V-block guides that are through-hardened and ground-superior to ensure the rigidity of the bed.

5. Automatic central lubrication for simplified maintenance, a powerful coolant system ensures machining accuracy.

6. For heavy-duty horizontal CNC lathes, there are three kinds of spindle speed variable speed: Hydraulic 4-steps, stepless in the steps; Manual 4-steps, stepless in the steps; Manual multi-steps.

| itm | unit | CK6163 | CK6180 | CK61100 | |

| Machining Range | Max. Swing over bed | MM | 630 | 800 | 1000 |

| Max. Swing over cross slide M380520630Max | MM | 380 | 520 | 630 | |

| Max. center distance | MM | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 1000/1500/2000/3000 | |

| Spindle | Spindle bore | MM | 105 | 105 | 105/130 |

| Spindle speed steps | 4 | 4 | 4 | ||

| Chuck | MM | Manual 400 3-jaws chuck | Manual 400 3-jaws chuck | Manual 630 4-jaws chuck | |

| Lathe bedded | Bed width | MM | 550/600 | 550/600 | 600/700 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 | 6000/8000 | 6000/8000 |

| Tool Turret | Number of tool turret | 4/6/8 | 4/6/8 | 4/6/8 | |

| Tool shank type | MM | 32*32 | 32*32 | 32*32 | |

| Working accuracy | Positioning accuracy | MM | X≤0.02 Z ≤0.025

| X≤0.02 Z ≤0.025 | X≤0.02 Z ≤0.025 |

| Repeatability Positioning accuracy | MM | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.010 | X≤0.015 Z ≤0.020 | |

| roundness | MM | ≤0.01 | ≤0.01 | ≤0.015 | |

| Diameter uniformity | MM | ≤0.03(length 300mm) | ≤0.03length 300mm) | ≤0.03length 300mm) | |

| Flatness | MM | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | ≤0.02(Dia.300mm) | |

| Surface roughness | ≤Ra3.2um Steel parts | ≤Ra3.2umSteel parts | ≤Ra3.2umSteel parts | ||

| Tailstock | Dia.of tailstock sleeve | MM | 100 | 120 | 150 |

| Tailstock sleeve taper | MT6 | MT6 | MT6 | ||

| Max. Tailstock sleeve travel | MM | 250 | 250 | 250 | |

| Motor | Spindle drive motor power | KW | 11 | 11 | 11/15 |

| Coolant pump power | KW | 120 | 120 | 120 | |