Menu

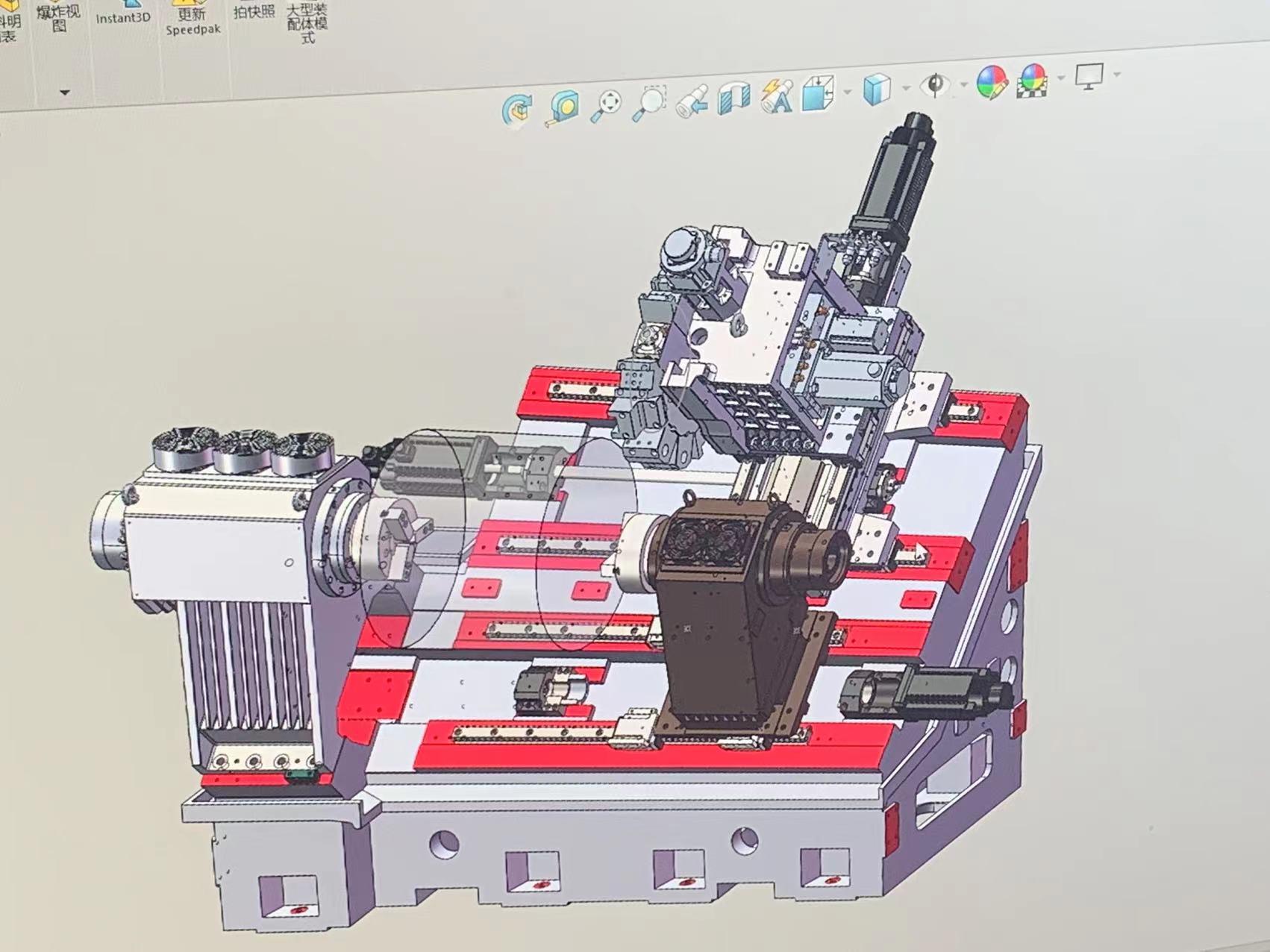

Heavy-duty casting So as to ensure the accuracy and stability of the machine tool

12-Station BMT45 driven tool turret

Y axis structure Realize precision machining of complex parts

Factory Direct Lathe Price & CE And SGS Quality Assurance

25+ Years in Lathes Manufacturing Online

3000+ Happy Partners

10000+Machine Tool Delivered

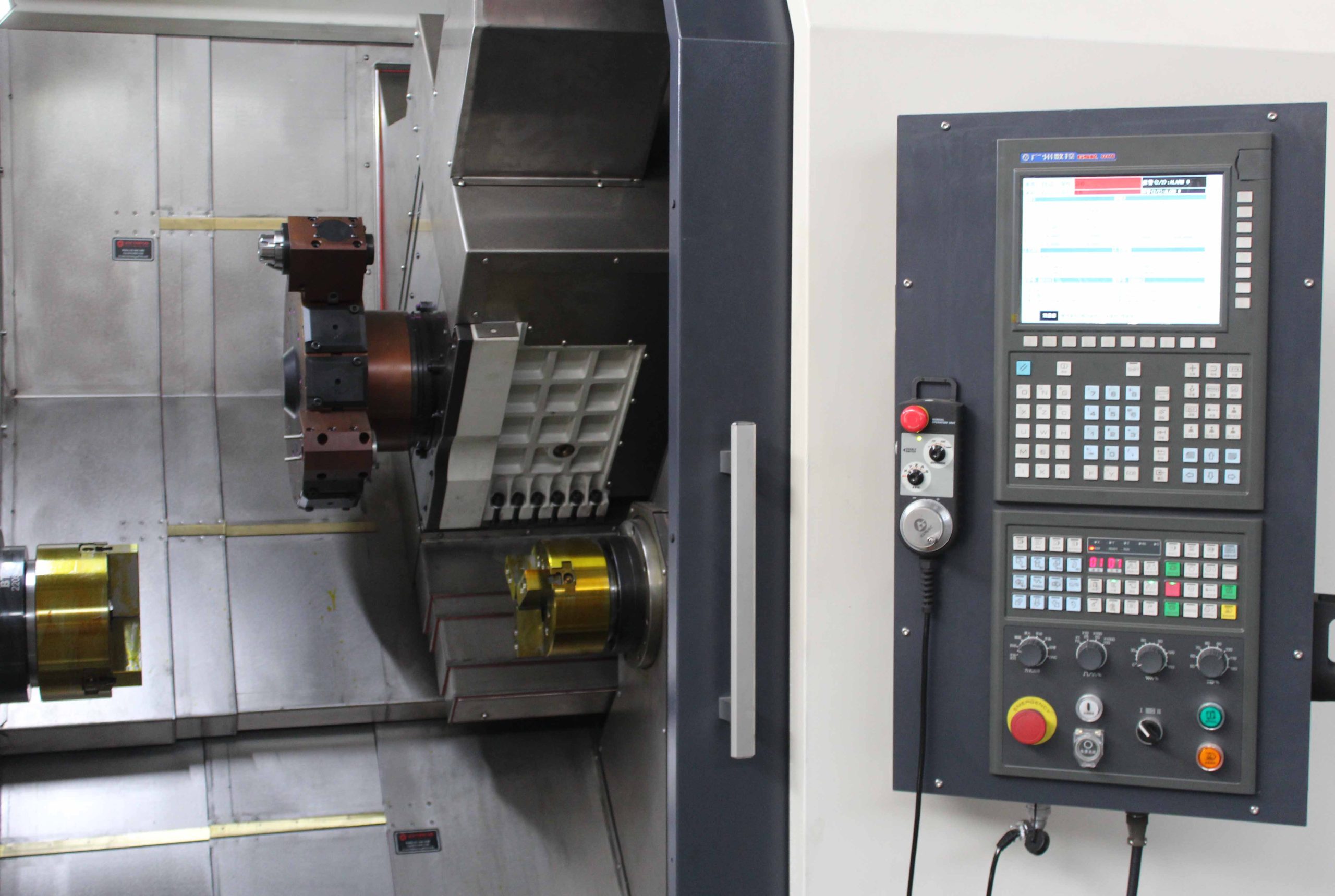

TCK50S Dual Spindle Cnc Turning Center Driven Tool Turret ,Yuzhuo machinery co,.lt a new cost-effective turning centerDriven Tool Turret type BMT45 or BMT55 No. of Driven Tool Turret stations 12nos. This machine can realize turn-milling function and carry out two-way butt joint processing for workpiece.With the development of science and technology, there is more and more demand for precision parts, so the requirements for lathes are getting higher and higher. Turning centers are the development trend, which can realize one-time processing and one-time molding of workpieces. Turn-milling compound processing, so as to improve the precision of the workpiece, save processing time, and reduce the user’s investment cost

1.GSK988TA/Siemens/Fanuc 2 .Colling system 3.Air conditioning 4.Automatic lubrication system

5.Lighting system 6.hydraulic system 8.Driven Turret Tool 12nos 9. chip coveyor and buket.

2 Driven tools (End face and Side face) 11.Cutting Cooling Unit

12.Leveling Screw and footings 13.Operating instruction 14.Basic Toolbox

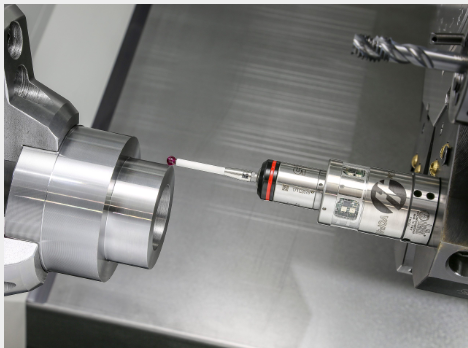

Wireless Probing – Lathe Machine And Automatic Tool Presetter Main brand Renishaw ,Haas….No Cnc lathe Should Be Without Probing ,Reduce setup times without having to know G-code or macro programming. Monitor tool wear and tool breakage, and reduce scrap creation

Lathe Machine – Wireless Probing

AAS WIPS FOR LATHES Wireless Probing Intuitive Probing System for cnc lathes (WIPS-L) is a complete probing package that includes a turret-mounted probe and optical machine interface, along with powerful software that guides the operator through the probing process with intuitive, easy-to-use templates WIPS can be used for rapid first-off part inspection, in-process reporting, and monitoring unattended machining operations. It can also be used to update work offsets to account for tool wear for ultimate part accuracy. The system includes the Haas Visual Programming System, macros, and spindle orientation. NOTE: Requires the purchase of a 25 mm ID toolholder.

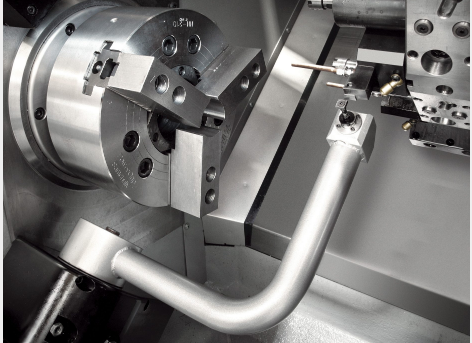

Lathe Machine – Automatic Tool Presetter

Lathe machine Automatic Tool Presetter increases part accuracy and setup consistency, while reducing setup times by up to 50%. The system features easy-to-use automatic and manual modes of operation, with a user-friendly interface for quick, conversational-style programming.

Includes User-Definable Macros option

Automatic, manual, and tool-breakage-detection operations

Increases tool setting accuracy and consistency

No macro programming required for operation

Outputs G-code to MDI, where it may be edited, or transferred into a program

Conversational-style templates for easy tool-setting operations

| Bed inclination | 45 degree | |

| Max.swing over bed | Spindle | 500mm |

| Sub-spindle | 400mm | |

| Max. Max. turning diameter | 360mm | |

| Max. length of workpiece | 450mm | |

| X AXIS | 350mm | |

| Y AXIS | ±45mm | |

| Z AXIS | Spindle Z1 | 500mm |

| Sub-spindle Z2 | 500mm | |

| X-axis rapid movement | 24mm/min | |

| Y-axis rapid movement | 10mm/min | |

| Z-axis rapid movement | 30mm/min | |

| Spindle nose | Spindle Z1 | A2-6 |

| Sub-spindle Z2 | A2-5 | |

| Spindle bore | Spindle Z1 | 66mm |

| Sub-spindle Z2 | 56mm | |

| Max. bar capacity | Spindle Z1 | 52mm |

| Sub-spindle Z2 | 42mm | |

| Spindle speed | Spindle Z1 | 50-4500rpm |

| Sub-spindle Z2 | 50-4500rpm | |

| Motor power | Spindle Z1 | 11KW |

| Sub-spindle Z2 | 5.5KW | |

| Chuck size | Spindle Z1 | 8寸 8 inches |

| Sub-spindle Z2 | 6寸6inches | |

| Driven Tool Turret type | BMT45 | |

| No. of Driven Tool Turret stations | 12nos | |

| Max. speed of driven tool | 500rpm | |

| Driven tool | End face driven tool | ER25/3000RPM |

| Side face driven tool | ER25/3000RPM | |

| Inner shank diameter | 25/ 32mm | |

| Outer diameter Shank diameter | 20X20mm 25X25mm | |

| Machine tool accuracy | X Z axis positioning accuracy | 0.012mm |

| X Z repeatability | 0.003mm | |

| Machine Size | 2900X1900X2200mm | |

| Machine weigth | 4.2T | |

How to ensure the quality of CNC machine tools?

Quality Assurance: Cnc Turning Center strictly implement CE /SGS quality standards and have received CE certification. This means our production lines feature advanced technologies that give manufacturing precision and accuracy. With sophisticated measuring and testing equipment in house, we check all incoming material and parts to meet your specifications. That’s why we are outstanding among the rapid prototyping companies in China. Learn more about our quality control system.

Free Instant Quote within 8 Hours

Generally, quotations will be delivered in 8 hours after submitting RFQs with clear information. You can get product price, freight, tax, delivery date, best processing method and transportation method, etc.

Lathe Machine Casting natural aging

All CNC lathes and castings of vertical machining centers in our company have undergone natural aging treatment, and the precision of the machine tools is stable and good